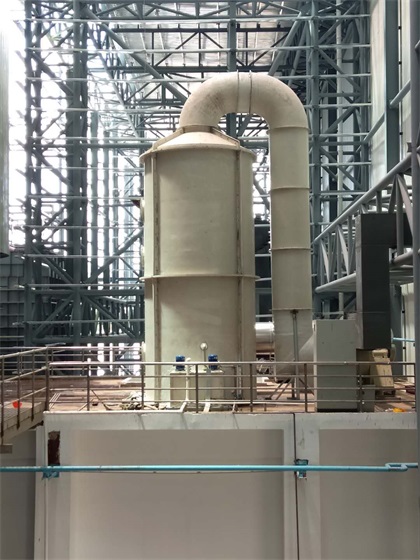

Dust removal equipment

Desulfurization and dust remover is one of the effective desulfurization and dust removal devices in China. It is a combination of water film dedusting and dust removal spray dedusting and dust removal as well as venturi.

Details

Desulfurization and dust remover is one of the effective desulfurization and dust removal devices in China. It is a combination of water film dedusting and dust removal, spray dedusting and dust removal as well as venturi. It is mainly applicable to the dedusting and desulfurization of coal-fired boiler flue gas and other industrial waste gas. The obvious advantage is that the dust is removed first and then desulfurized, which reduces the wear of the equipment caused by the dust. The equipment has high dust removal rate, good desulfurization effect, stable performance, long service life and simple operation. The main body of the equipment is made of anti-corrosion and wear-resistant materials, which fundamentally solves the problems of corrosion and wear of other desulfurization dust collectors

Under the action of induced draft fan, 90% of dust particles can be removed by dry dedusting equipment, and then the positive pressure generated by induced draft fan enters the venturi inlet of dedusting and desulfurization equipment Secondary humidification: after entering the equipment, the flue gas spirals up along the inner wall of the equipment, and reacts fully with the water film on the inner wall of the tower again. At the same time, the fine dust and water flow in the flue gas return to the bottom of the tower to discharge, and the flue gas is fully washed again. The sulfur dioxide in the flue gas will react fully with the alkali absorbent after washing, and almost all the sulfur dioxide and smoke in the flue gas are removed. It is clean The flue gas will enter the dehydration area for dehydration treatment, and then be discharged from the chimney. There will be a certain amount of water in the flue gas. It is normal for the flue gas to appear milky white. (untreated smoke may be black or yellow, black may be excessive smoke, and yellow may be sulfur dioxide). The used water will flow into the sedimentation tank for sedimentation and reuse.

?

?